Restaurant Food Safety Checklist

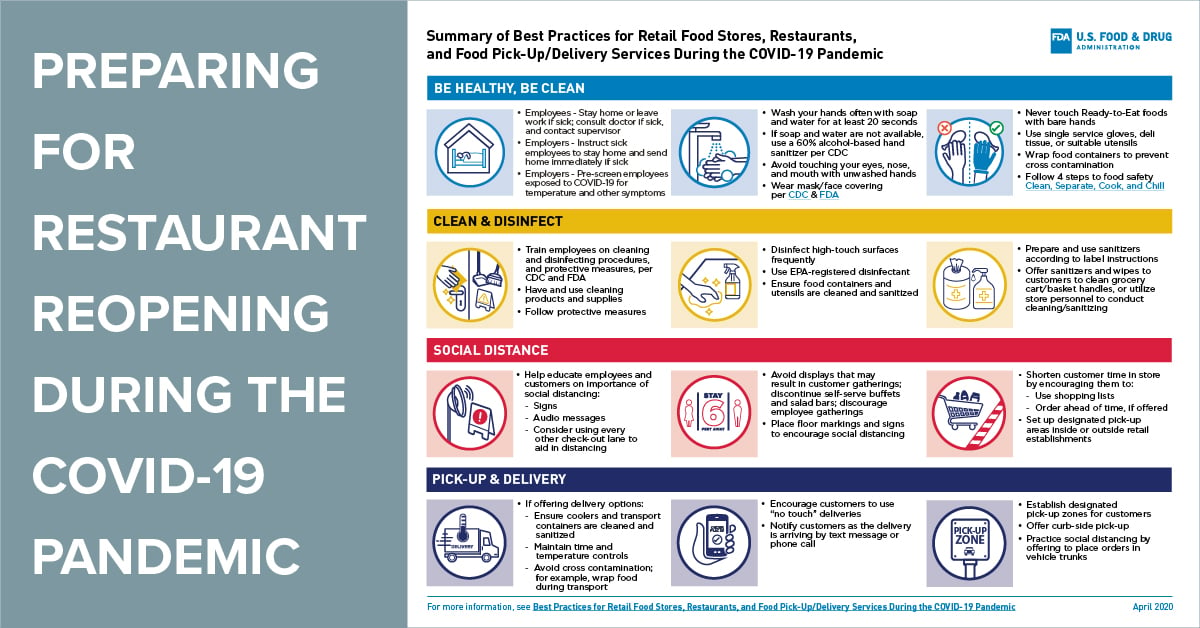

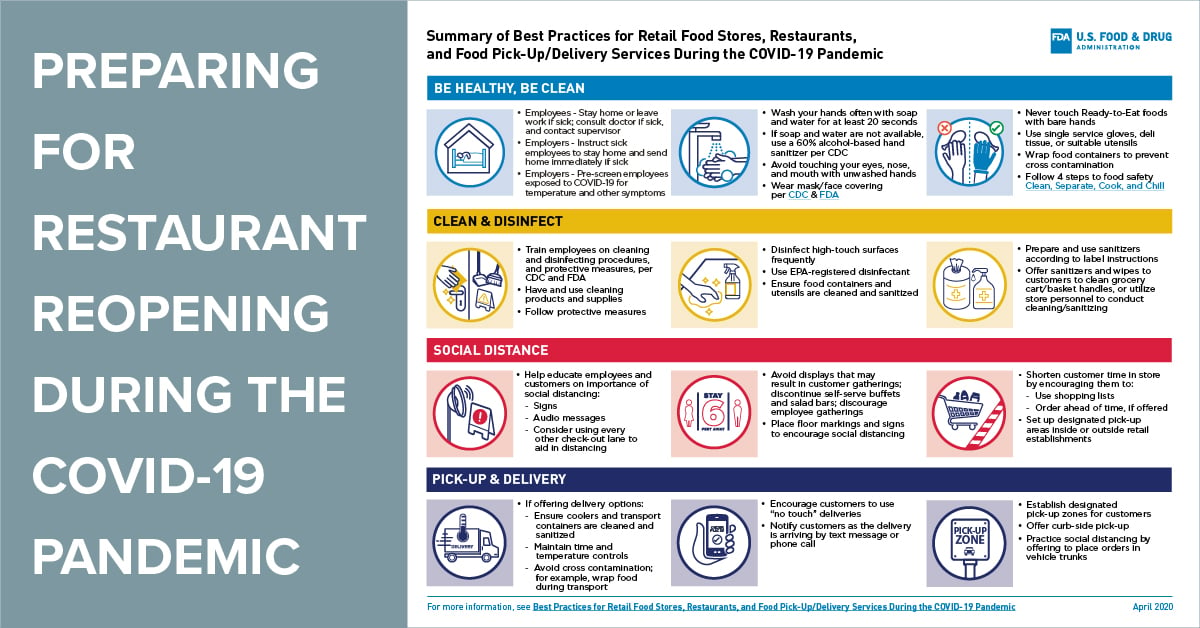

Best Practices for Re-Opening Retail Food Establishments During the COVID-19 Pandemic

Getting ready to reopen your food establishment? The FDA is providing a food safety re-opening checklist for previously closed retail food establishments or those that have been open with limited service related to the COVID-19 pandemic. This checklist addresses key food safety practices for retail food establishments to consider when re-opening and restarting operations.

Facility Operations

- Are signs posted on how to stop the spread of COVID-19 and promote everyday protective measures?

- Are the premises in good order, including fully operational utilities and equipment? (e.g. electrical, lighting, gas services, and proper ventilation; hood systems for fire prevention; garbage and refuse areas; and toilet facilities)

- Are all areas of the food establishment, including restrooms and waiting areas, properly cleaned, stocked, sanitized, or disinfected, as appropriate?

- Are the facilities checked for pest infestation or harborage, and are all pest control measures functioning?

- Are ventilation systems including air ducts and vents in the facility clean, free of mold, and operating properly?

- Is there increased circulation of outdoor air (as much as possible) by, for example, opening windows and doors or using fans? (Do not open windows and doors if they pose a safety risk to children using the facility.)

- Are high touch self-service containers and items requiring frequent hand contact removed from use (e.g. seating covers, tablecloths, throw rugs, condiments such as ketchup bottles and salt/pepper shakers, and reusable menus)?

Water, Plumbing, and Ice

- Is potable water available throughout the facility?

- Are the water and sewage lines working?

- Is there hot and cold water?

- Are all water lines flushed, including equipment water lines and connections, according to the manufacturer’s instructions?

- Are ice machines and ice bins cleaned and sanitized?

- Food Contact and Non-food Contact Surfaces (Clean, Disinfect, Sanitize)

- Are necessary sanitizers and disinfectants that meet EPA’s criteria for use against SARS-CoV-2 available and used per label instructions to clean and disinfect the facility during hours of operation?

- Are food contact surfaces and counters cleaned and sanitized? (Wash, rinse, and sanitize food contact surfaces, food preparation surfaces, and beverage equipment after use.)

- Are common use areas such as restrooms being cleaned and disinfected more frequently?

- Are high-touch areas and equipment cleaned and disinfected (e.g. doorknobs, display cases, equipment handles, check-out counters, order kiosks, and grocery cart handles)?

- Are sufficient stocks of single-service and single-use articles (e.g. tableware, carryout utensils, bread wrappers, and plastic wrap) available? If not, ensure all reusable food service items are handled with gloves and washed with dish soap and hot water or in a dishwasher. Employees should wash their hands after removing their gloves and after directly handling used food service items.

- Are staff properly trained on cleaning procedures to ensure safe and correct application of disinfectants?

- Has a disinfection schedule or routine plan been developed? Ensure sufficient stocks of cleaning and disinfecting supplies to accommodate ongoing cleaning and disinfection.

Food Temperature Control

- Are all coolers, freezers, and hot and cold holding units functioning?

- Are all coolers, freezers, and hot and cold holding units clean, sanitized, and protected from contamination?

- Are calibrated thermometers available and accurate to check equipment and product temperatures to ensure food safety/HACCP plans are executed as designed?

Product Inspection, Rotation

- Has all food been examined for spoilage, damage, expiration, or evidence of tampering or pest activity? If needed, was such food appropriately discarded?

- Is food properly labeled and organized, such that receiving date and rotation is evident?

- Are all food, packaging, and chemicals properly stored and protected from cross contamination?

- Has contact been made with suppliers in the supply chain to ensure deliveries are scheduled and able to be fulfilled?

Warewashing Equipment

- Is your 3-compartment sink clean and equipped with detergent and sanitizer?

- Is your warewasher clean and functioning and equipped with detergent and sanitizer (single temperature machine, 165°F) or reaches 180°F rinse (high temperature)?

- Do you have sanitizer test strips available and are the test strips appropriate for the sanitizer being used?

Handwashing Stations

- Have you trained and reminded employees of effective hand hygiene practices including washing hands with soap and water for at least 20 seconds, especially after going to the bathroom, before eating, and after blowing their nose, coughing, or sneezing?

- Are all the handwashing sinks accessible and fully stocked (e.g. soap, paper towels, hand wash sign, and trash bins)?

- Are paper towels and trash cans available in the bathrooms so doors can be opened and closed without touching handles directly?

- Are all the handwashing sinks functional and able to reach 100⁰F minimum?

- Have you considered using hand sanitizers (minimum 60% alcohol), as appropriate, in multiple locations to encourage hand hygiene by both customers and employees to supplement hand washing?

Employee Health / Screening

- Do you have a protocol to check employee health and personal hygiene practices within your food establishment?

- Are you following CDC guidance and practices for employee health checks/screenings?

- Have you checked CDC and local regulatory/health authority guidance for employees returning to work?

- Is there a plan to monitor and respond to a higher than normal level of absenteeism?

- Is there a plan or policy for, and an adequate supply of, personal protective equipment (PPE) and/or cloth face coverings? Cloth face coverings should only be used if PPE is not required and changed as needed if worn.

Social Distancing

- Has the facility taken measures (e.g. tape on floors/sidewalks, partitions, and signage on walls) to minimize face-to-face contact that allows, to the extent possible, at least a 6-foot distance between workers, customers, and visitors?

- Have you limited offering self-serve food or drink options, such as buffets, salad bars, and drink stations? As local regulatory/health authorities lift levels of restrictions, limit use with additional monitoring.

- Have you restricted the number of employees in shared spaces, including kitchens, break rooms, and offices to maintain at least a 6-foot distance between people?

For further advise and resources, connect with your local regulatory/health authorities to discuss the specific requirements for your retail food establishment prior to re-opening.

Plascon is dedicated to providing maximum safety in every product we make. Our food grade bags and liners are all FDA & USDA approved, and BRC 'AA' certified to ensure the highest quality and sanitation for your products. Visit our website for your Box Liners, Cook Chill Bags, and Saftea® Tea Urn Liners and learn how we can help you deliver safe, hygienic food products to your valuable patrons.

*This list was provided by the FDA website and can be found at this link.